Production process for mattress structures

The phases of creating Box and Sandwich for mattress manufacturing

At Inver, we put a lot of care into the production process of mattress structures, adopting a meticulous and attentive approach at every stage. A fundamental element of our commitment is the use of cutting-edge machinery, which plays a crucial role in creating quality products. Our attention to detail is evident in every phase, from product design to its creation, whether it's Box or Sandwich.

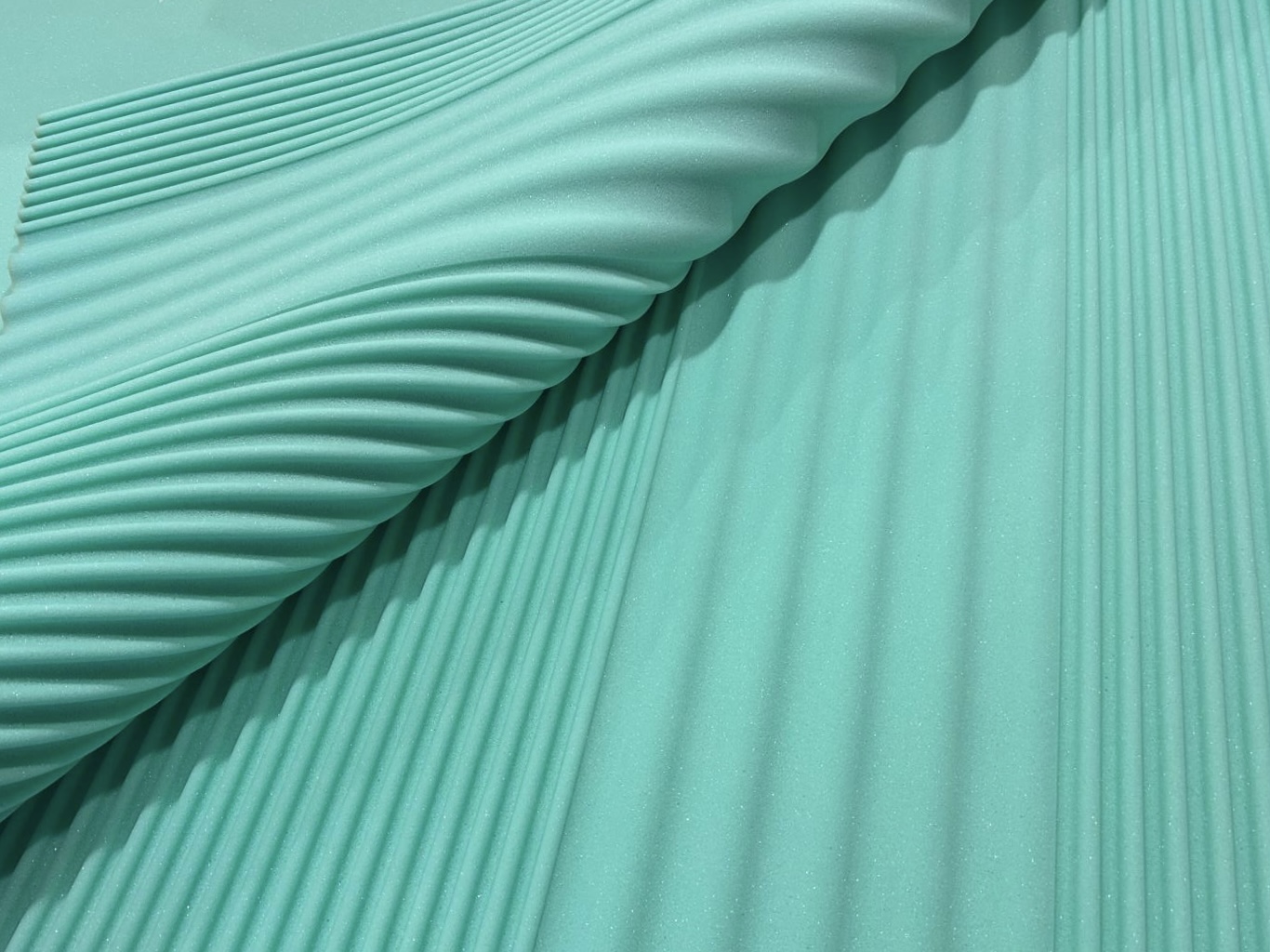

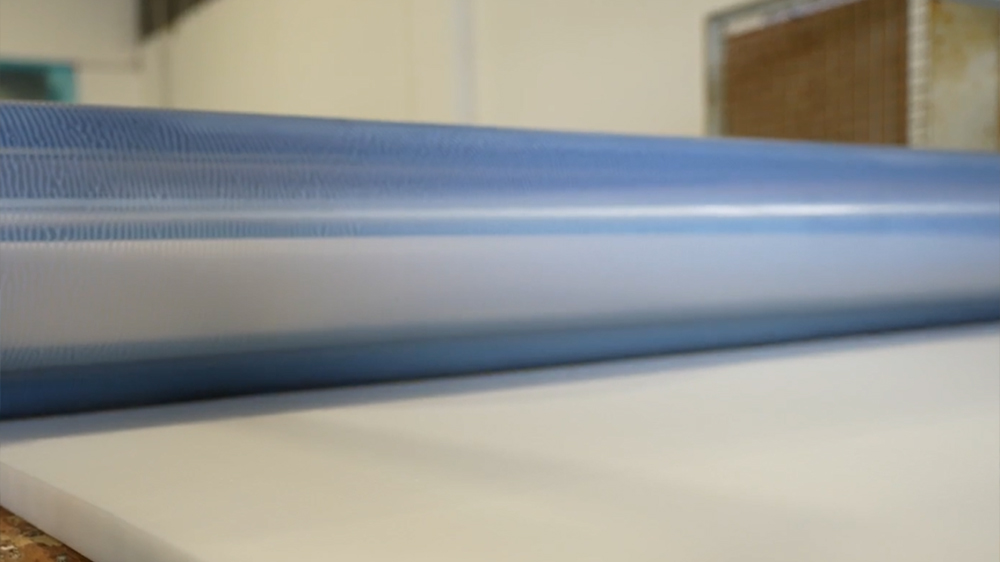

Cutting of the raw block

For both types of mattress structures, with and without springs, we start from the cutting of the raw block of expanded polyurethane. Using a specialized machine, sheets of precise dimensions and the required height for the final product are cut.

Gluing

Once cut, the sheets are transferred to the gluing department. Using a special automatic gluing machine, the glue is uniformly distributed on the sheet. This step is crucial to ensure the solidity and durability of the mattress.

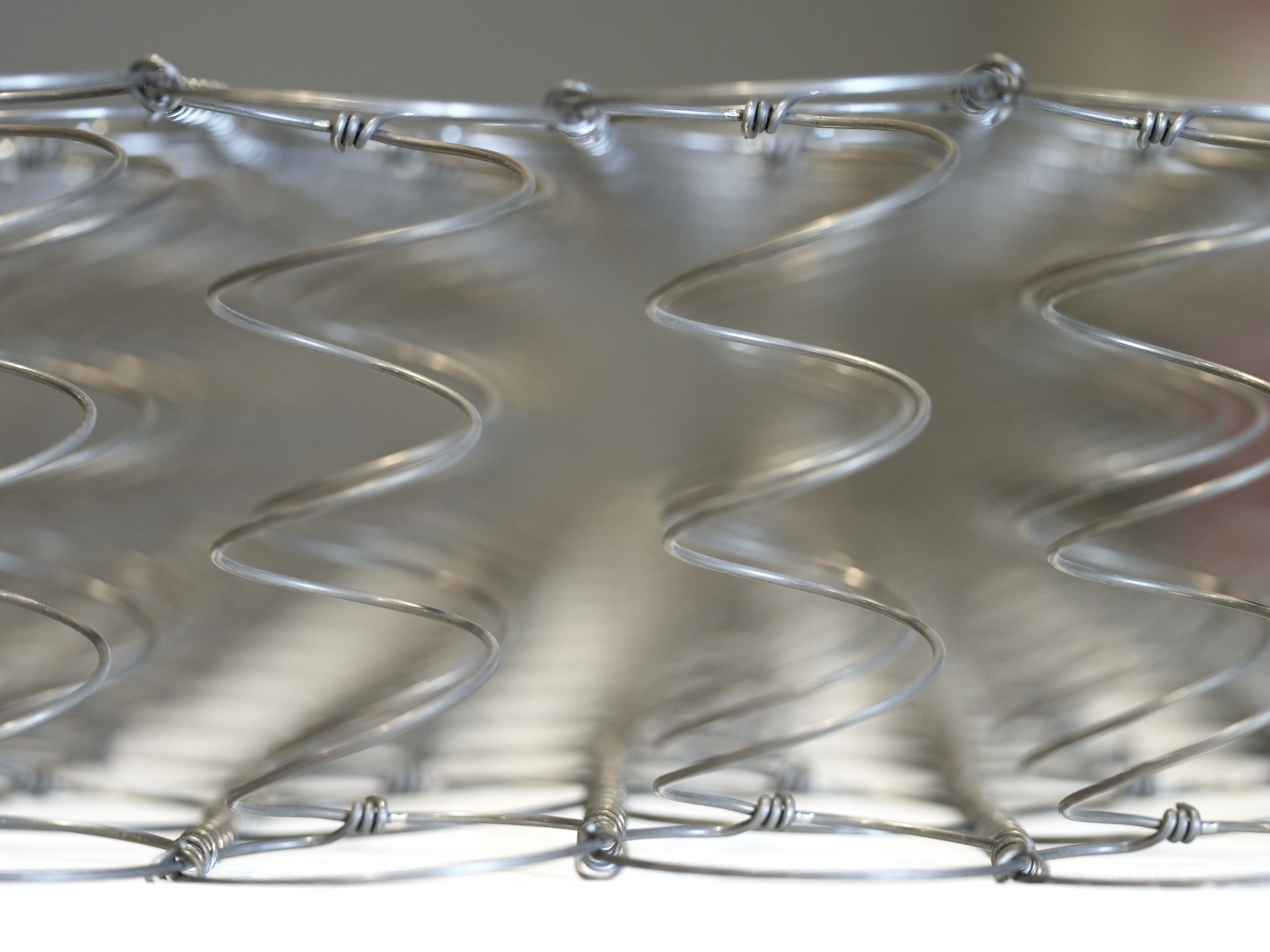

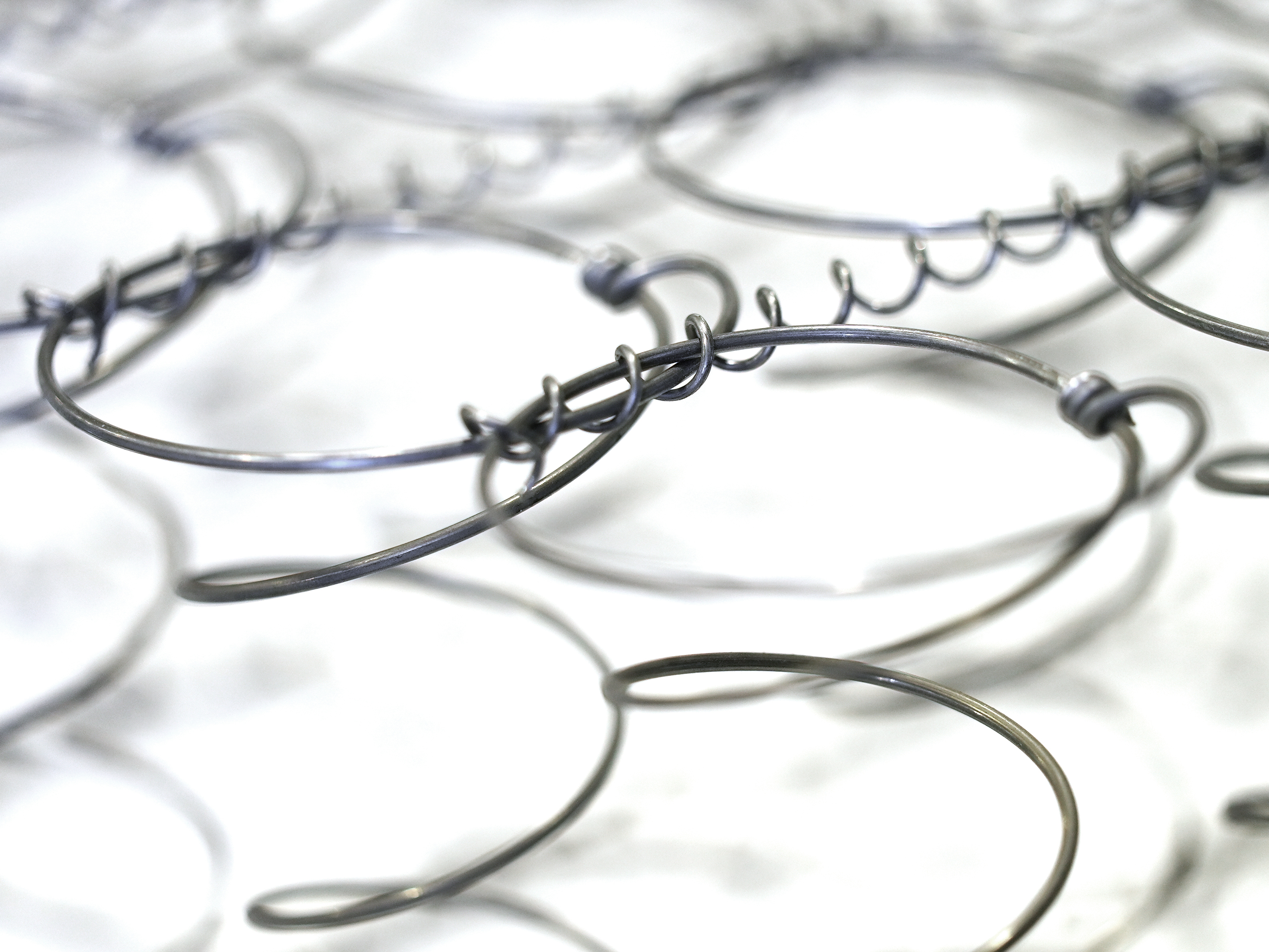

Assembly

In the assembly process, the sheets are used to compose the structure. For spring mattresses, the process involves the accurate positioning of the side pads and the insertion of the spring system, creating the internal core of the mattress. For mattresses without springs, the assembly process is similar, but without the addition of the spring system.

Final packaging and shipping

After the completion of assembly, the product goes through the final phase of packaging and shipping. Each structure, carefully checked to ensure maximum quality, is carefully packaged and prepared for shipment.