Bonnel spring production

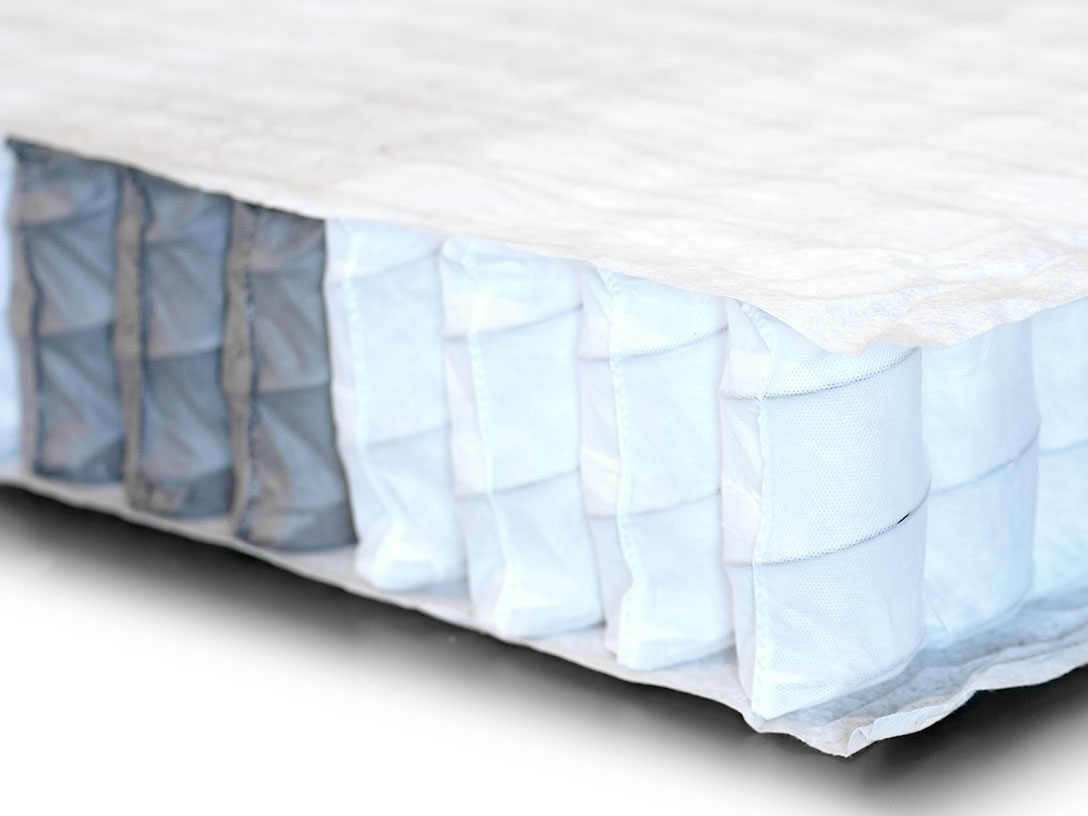

Traditional springing or orthopedic springing with bonnel springs

For years we have specialized in the production of bonnel springing, a reliable and versatile springing system. We offer customized bonnel springing solutions, able to adapt to individual preferences and needs.

The bonnel springing system, also known as traditional springing or orthopedic springing, is the most common for mattress manufacturing.

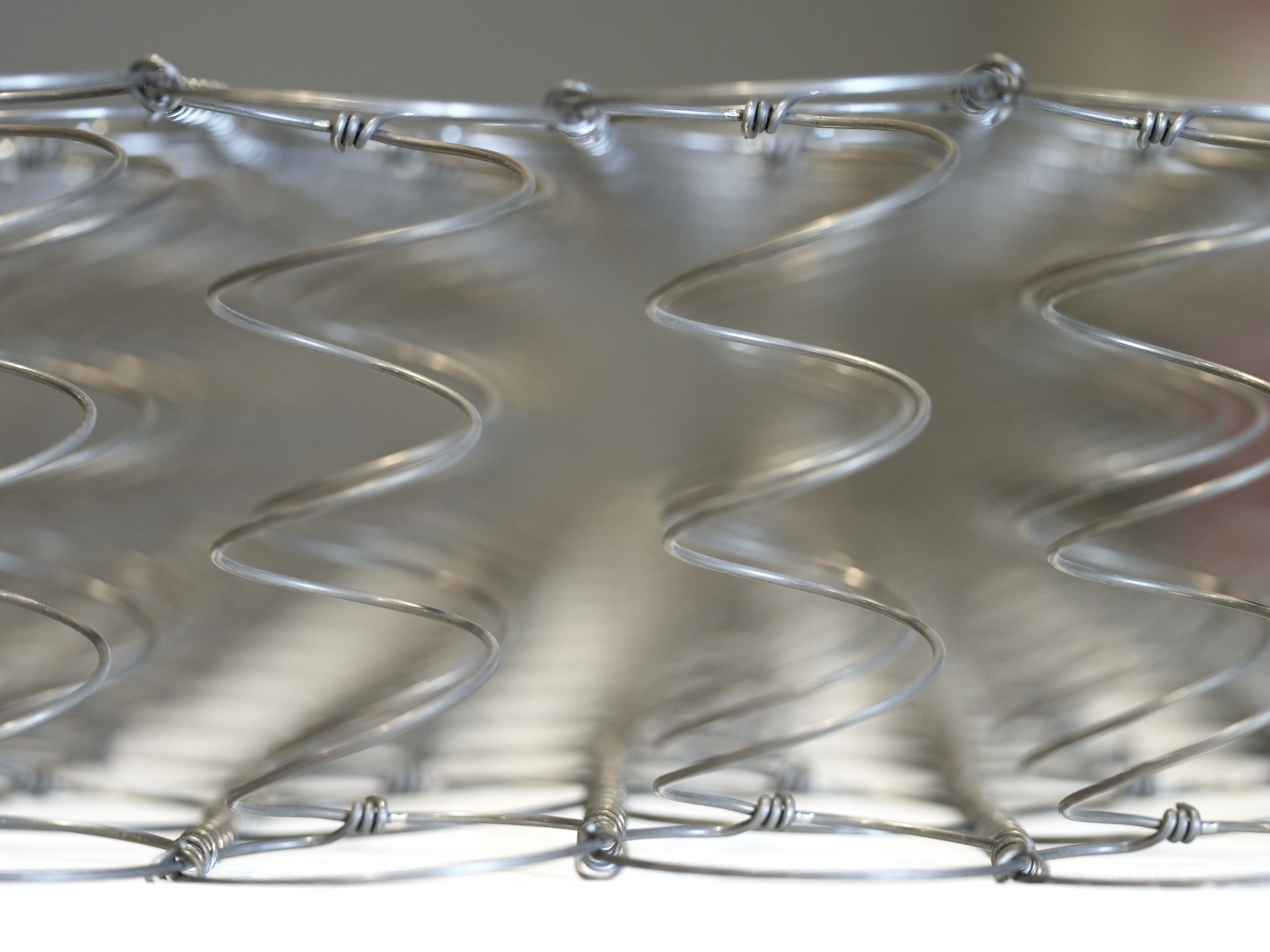

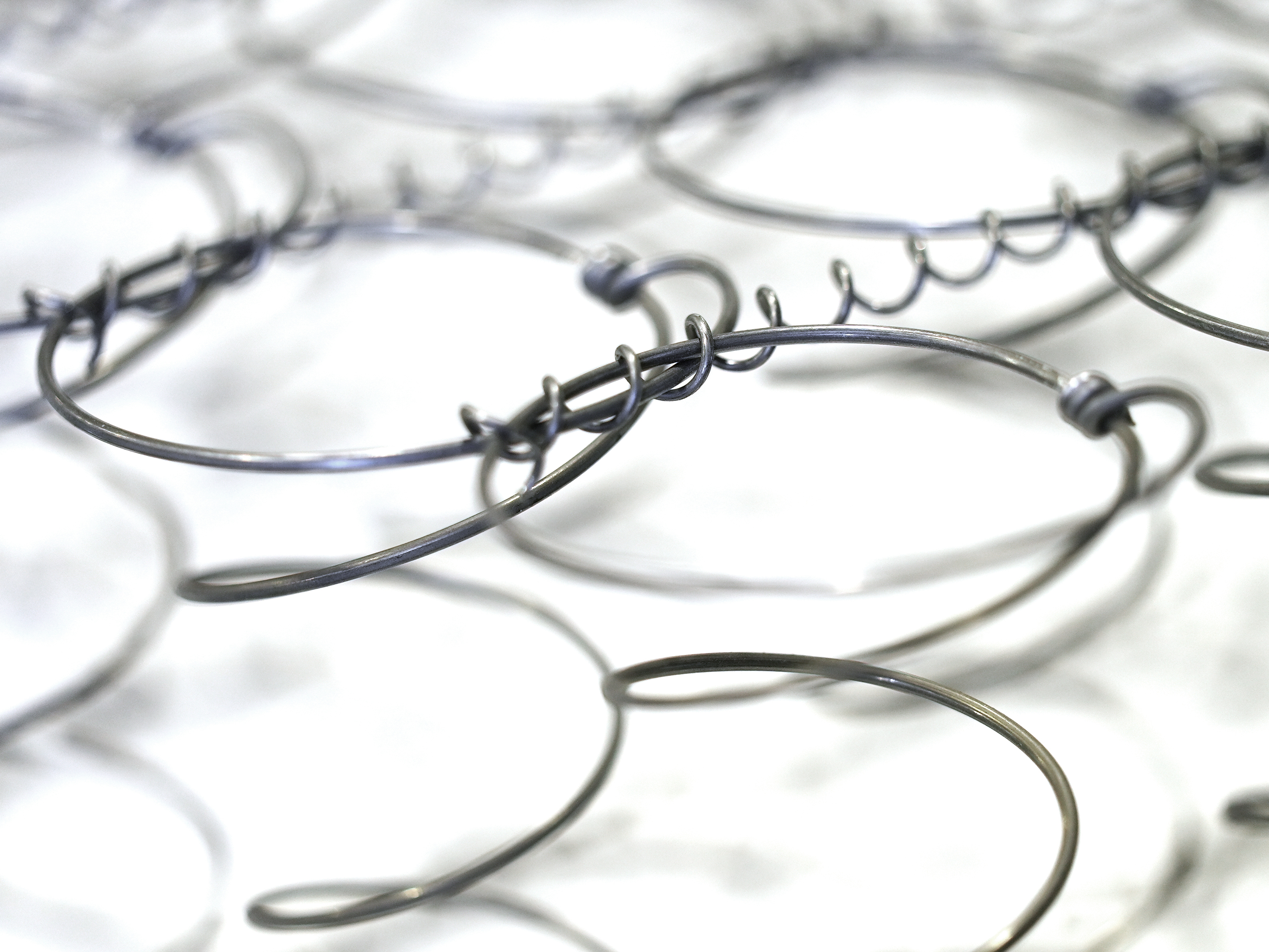

This particular springing system is composed of rows of springs that are assembled through a steel wire spiral. The spiral is fundamental as it connects each spring on all four sides, ensuring the transmission of stresses to nearby springs.

The rigidity in the production of bonnel springing is determined by the quantity of springs that compose it, with an interval from a minimum of 96 to a maximum of 132 springs per square meter.

By varying the number of rows of springs it is possible to adjust the rigidity of the springing.

The springs we use for the production of bonnel springing are made with a very high quality steel wire with a diameter of 2.20 mm, while the assembly spirals are made with steel wire with a diameter of 1.30 mm.

The characteristics of bonnel springing: why choose it

Bonnel springing can be chosen for its:

- robustness - bonnel springs maintain their shape over time, guaranteeing constant support

- durability - thanks to the ability of bonnel springs to quickly recover their original shape, the springing maintains high performance over time

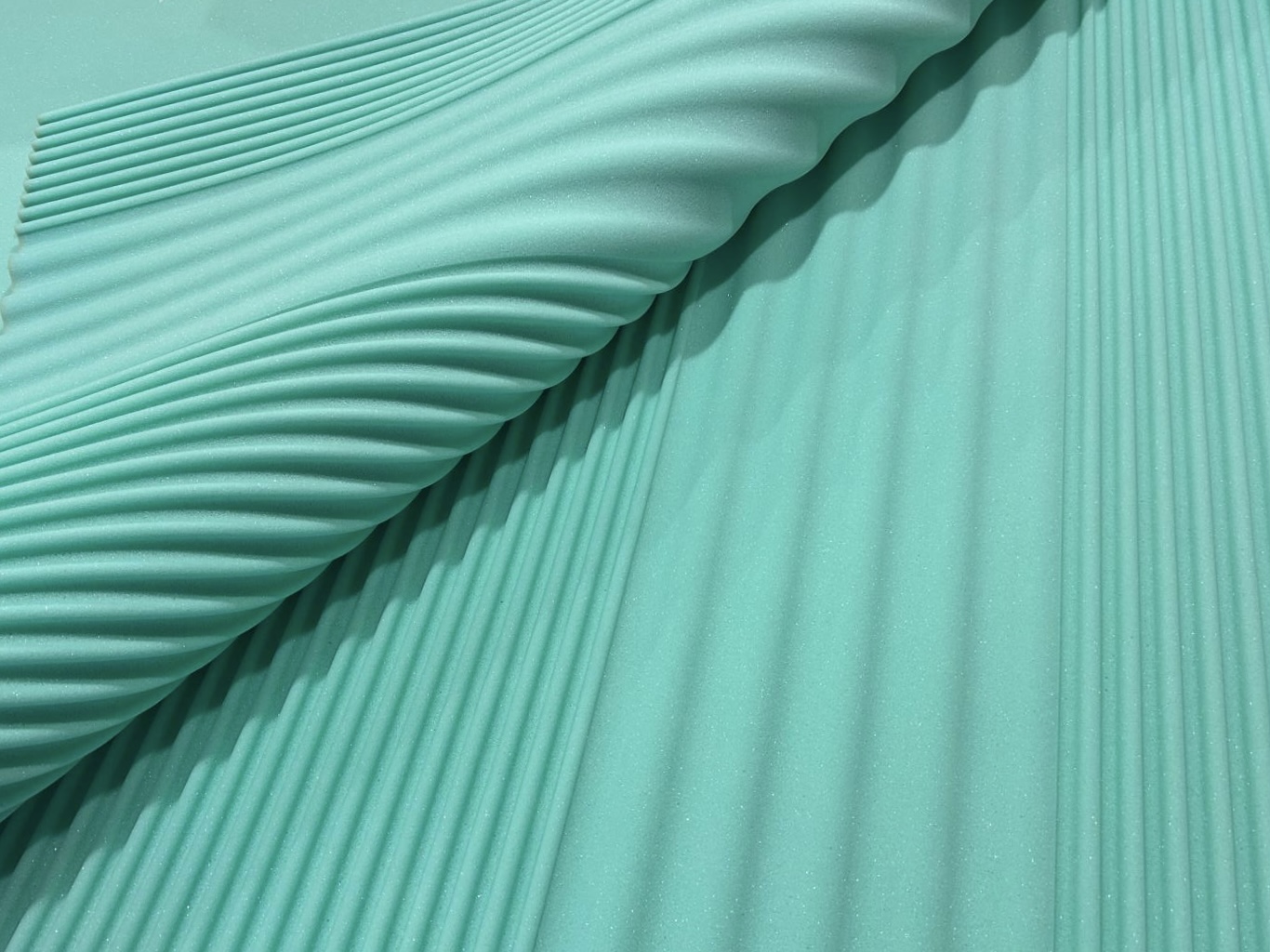

- good ventilation and breathability - the open structure of bonnel springs promotes optimal air circulation

- uniform support - through the regular arrangement of the springs, uniform support is obtained over the entire surface