Company producing materials for mattresses

Inver | Production of springs, spring systems and boxes for mattresses since 1984

1984

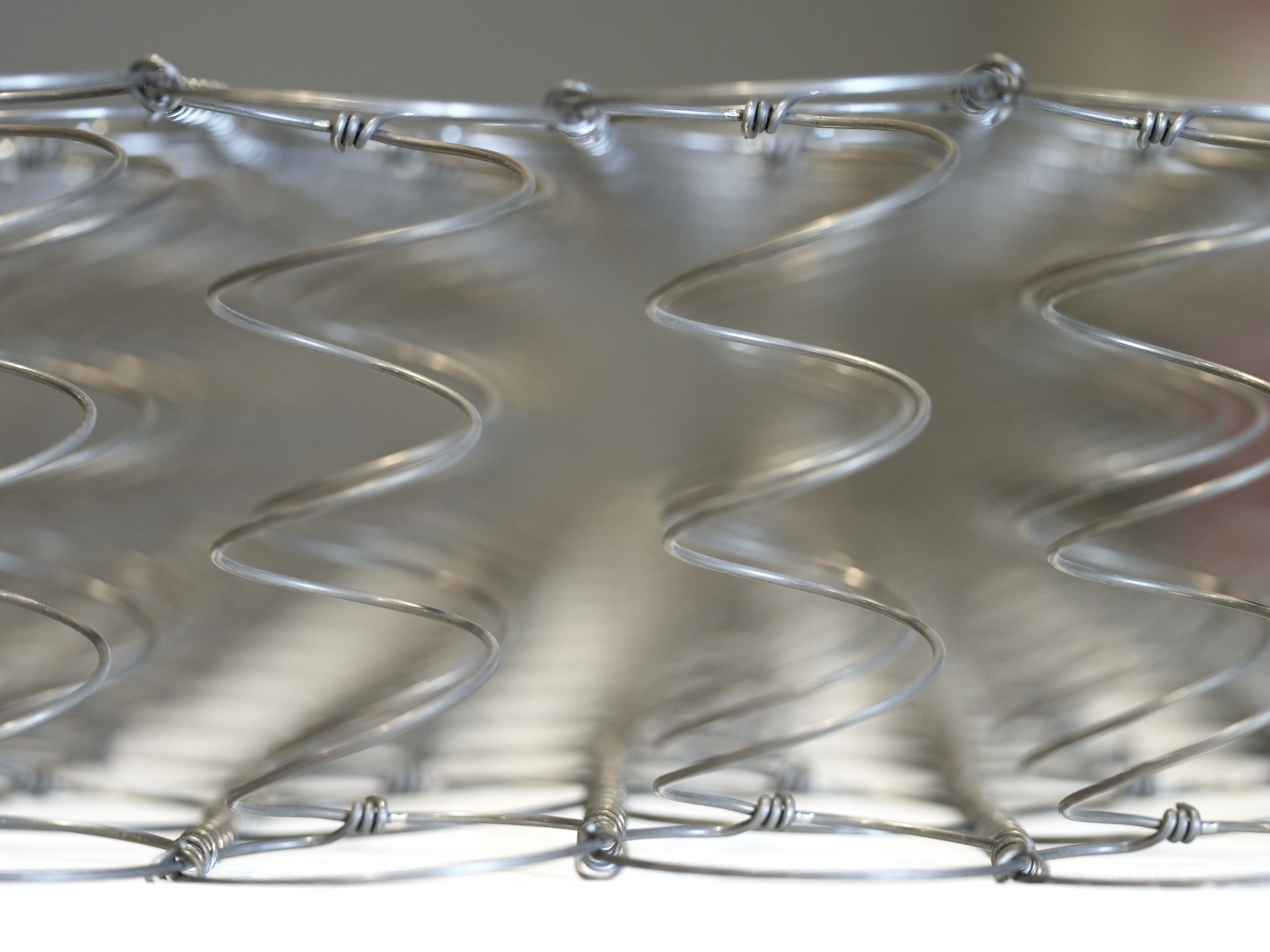

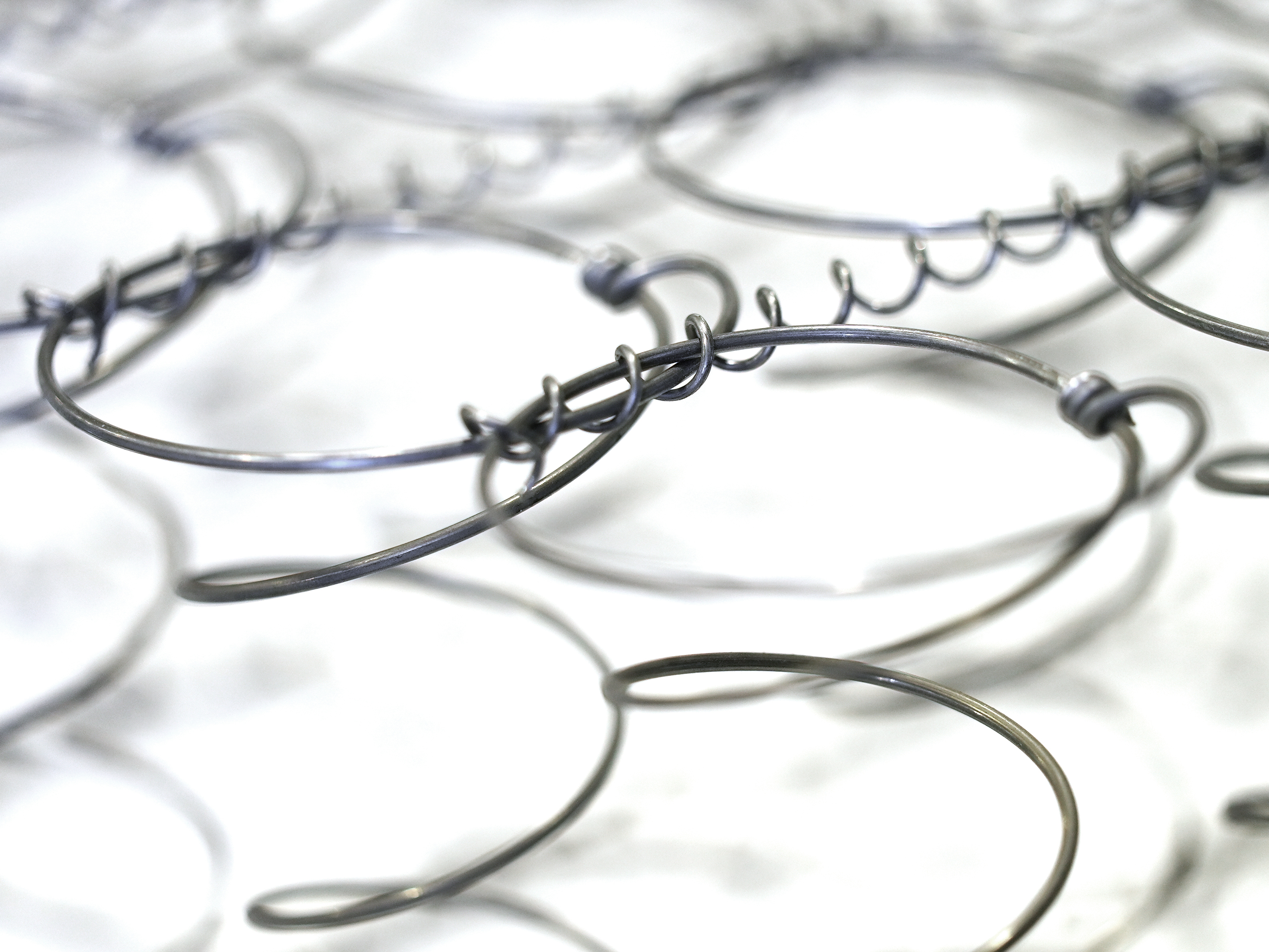

Inver, a company specializing in the production of materials for mattresses, was founded in 1984 as a spring factory exclusively dedicated to the manufacture of springs and spring systems for mattresses. Over the years, the company has undergone significant transformations, expanding the distribution of its products between Northern and Central Italy and broadening the types of processes carried out.

2010

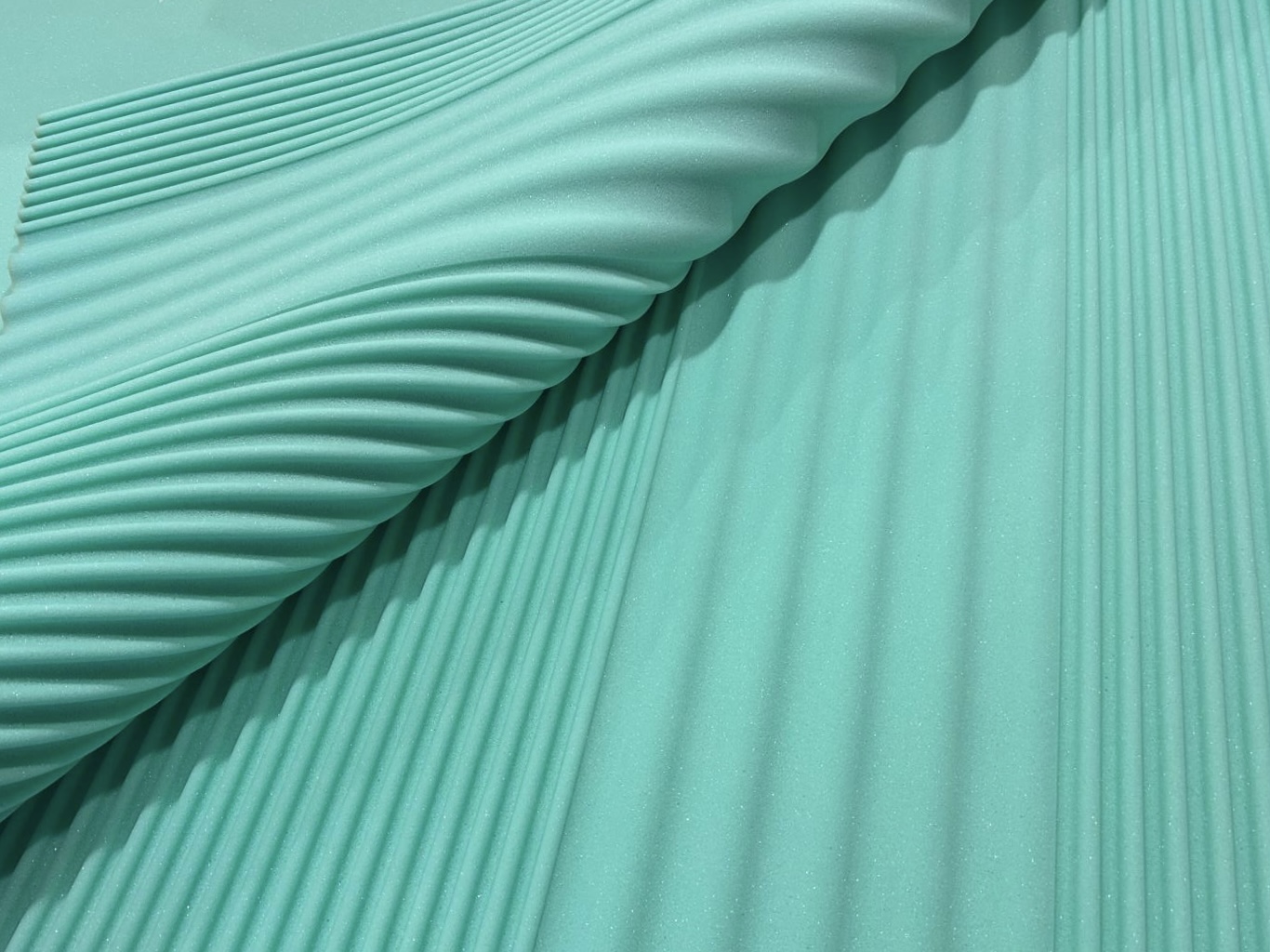

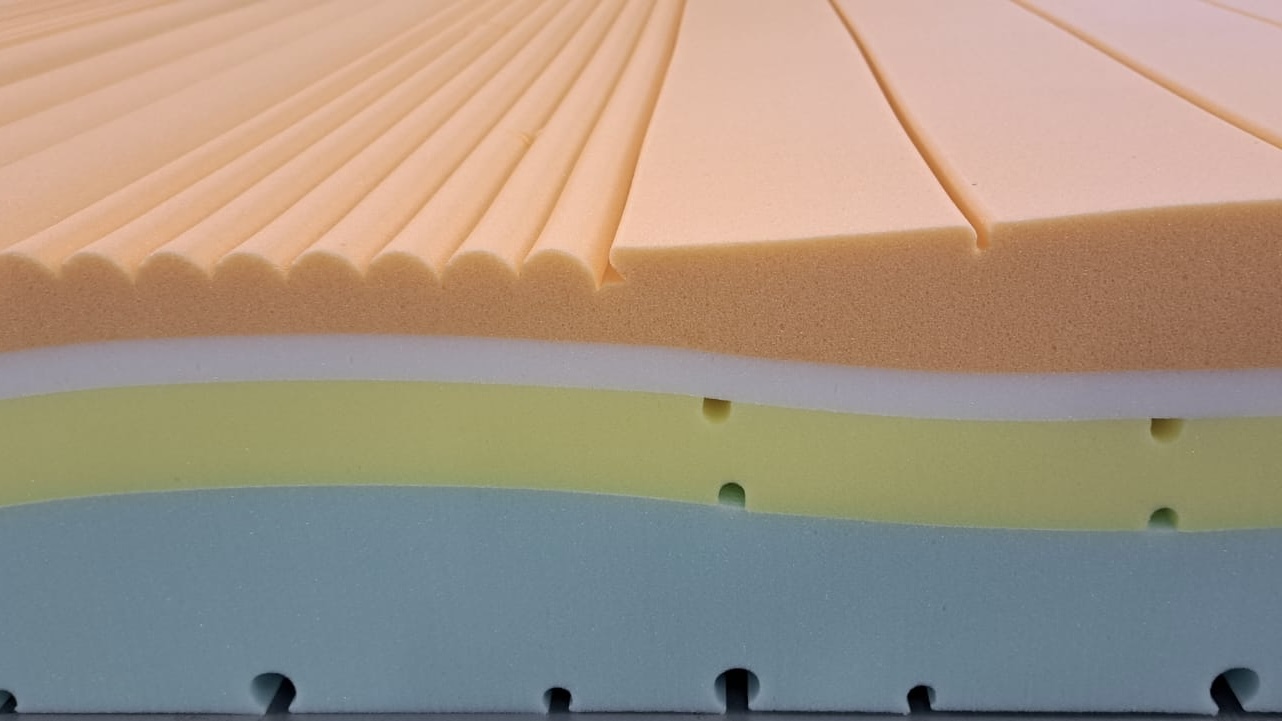

In 2010, in fact, the company made the strategic decision to expand its range of materials for the production of mattresses by introducing the box system. This innovative technology involves coating the spring with polyurethane, thus creating a high-quality semi-finished product.

2018

Starting from 2018, this solution becomes the core business, a symbol of the constant pursuit of excellence in the mattress material production sector.

2022

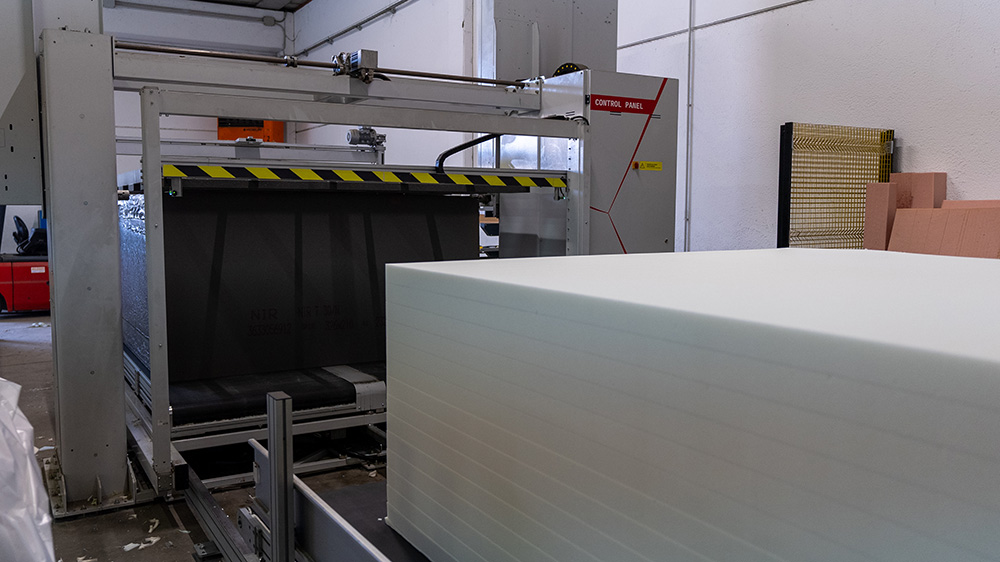

In 2022, Inver created its own internal cutting department: the installation of a state-of-the-art machine allows the company to perform precise cuts and shaping directly from the raw block of polyurethane, thus guaranteeing impeccable and totally customized final products.

Our mission

Our commitment to excellence emerges in every phase of the production process: the use of precision machinery and the use of excellent quality materials contribute positively to the durability and comfort of the mattresses that take shape thanks to our materials.

Our company stands out for supplying manufacturers and companies in the sector with materials intended for the production of high-level mattresses. Carefully designed, these materials transform rest into an authentic experience of well-being, guaranteeing lasting comfort and unsurpassed quality.

Why choose Inver

Our strengths

Use of Made in Italy products

We select exclusively Made in Italy materials, ensuring quality and authenticity for every solution offered.

Hyper-personalization of solutions

We offer tailor-made solutions, adapting materials to the specific needs of each customer.

Latest generation machinery

We adopt cutting-edge technologies and high-precision machinery to ensure efficient and high-quality production.

Green energy

Our company is committed to the use of sustainable energy thanks to the installation of photovoltaic panels on our warehouses, thus contributing to reducing environmental impact.

Recycling of waste polyurethane

We operate an efficient process of recycling waste polyurethane through the use of a compactor for rubber waste, integrating it into a recovery system.

Innovation

Professionalism

Ad hoc solutions

Environmental sensitivity

Experience

Quality control